Mining

Ozone is a sustainable and environmentally safe treatment for water that is chemical-free, energy-efficient and cost-effective.

For the mining industry, Aclarus Ozone provides a water treatment solution for the operational challenge of process wastewater.

Ozone Advantages for the Mining Industry

Mining operations are required to treat process water before it is discharged into the surrounding environment. Ozone is increasingly used in the mining industry because it has numerous advantages over traditional disinfection methods. Supplementing or replacing an existing system with an ozone system has the potential to boost a company’s advantage over its competitors.

Ozone has the following advantages for the mining industry:

✓ It is chemical-free and breaks down to oxygen after treatment; produces no harmful by-products;

✓ Provides rapid and complete decomposition of thiol collectors, ammonia nitrite, cyanides, cyanates, and thiocyanates;

✓ Quickly neutralizes unhealthy minerals in the water, like iron, sulphur and manganese;

✓ Removes contaminants of emerging concern (CEC’s), such as pesticides, organic matter, various microbes, pharmaceuticals and micro-plastics;

✓ Produced Onsite and On Demand, removing the need to purchase, store and physically handle chemicals.

✓ Is fully automated; has minimal operator requirements;

✓ Is a cost-effective treatment that enables mine operators to achieve regulatory compliance and reduce fees and fines

Ozone Water Treatment

Is chemical-free and a sustainable solution;

Is fully automated with remote access, for ease of use and integration;

Completely disinfects and removes contaminants, including colour, for assured re-use quality;

Reduces or eliminates fees on discharge and incoming water;

Has low life-cycle costs with a quick ROI.

Aclarus Water Treatment Solutions

Process Wastewater

Mining operations are required to treat process water before it is discharged into the surrounding environment. This wastewater may contain many kinds of contaminants, including:

Cyanide compounds: Cyanide, Cyanate, Thiocyanate

Nitrogen compounds: NH3, NO2

Collectors and Flotation Agents: Xanthates, Dithiophosphates

Metals: Iron, Manganese, Zinc, Copper

Ozone can be used “on demand” to solve multiple water treatment issues safely and efficiently. In the mining industry, it is a highly effective and affordable solution for removing cyanides, nitrogen species, thiol collectors and metals from process water before it is discharged.

Cyanide

Cyanidation is the process of using cyanide to transform gold into a water-soluble form which allows for its extraction and processing. Cyanidation is the most common form of gold extraction. Worldwide, one billion tonnes of ore are processed by cyanidation.

Because cyanide is highly toxic, it must be destroyed in the process water before it is released into the surrounding environment. Ozone is an effective treatment option for cyanide compounds, as they quickly decompose in the oxidation process.

Nitrogen

Ozone will also easily oxidize nitrite to nitrate, and if pH is adjusted, ozone can effectively convert ammonia to nitrate. The dose needed for oxidation of NO2 to NO3 is approximately 3.4 kg O3/1kg NO2, which makes it an economical solution for treatment of nitrites.

Figure 3. Graph showing the effect of pH on oxidation of ammonia to NOx. – COULD ADD A GRAPH HERE FROM THE ORIGINAL DOCUMENT.

Collectors

Sulfide ores are typically treated with froth flotation agents, such as thiol collectors like xanthates, dithiophosphates, and dithiocarbamates. These collectors can cause sulfide minerals to “repel” water and form bubbles. Residual flotation agents or their by-products can affect the chemistry of the mine processes and/or are highly toxic to aquatic ecosystems.

It is therefore necessary to remove or reduce flotation reagents from process water, either to allow for recirculation of the water or for discharging it into the environment. Studies have shown that oxidation with ozone is highly effective at degrading and removing thiol collectors like dithiophosphates and xanthates.

Metals

Regardless of the source of the water, ozone and post-filtration will quickly removed iron, manganese, sulphur, lead, arsenic and other metals from process water.

Other technologies leave gaps in water treatment that can be filled by ozone:

Chlorine produces multiple types of chemical by-products and is slower than ozone in removing contaminants. It also is dangerous to handle and gives off Greenhouse Gas Emissions (GHG);

Hydrogen Peroxide does not produce harmful by-products, but it is slow to act on removing contaminants and its effectiveness-to-cost ratio is poor. It also produces GHG and is dangerous to handle.

Mining process water will vary greatly depending on the type of mining operation. Knowing the specific contaminants and their levels in the water helps determine the required ozone demand. Given the critical nature of the industry, wastewater from mining production requires careful system design to ensure safety and efficiency.

Ozone Aclarus engineers assess the treatment needs for each mining operation and design a solution to fit the need through testing and/or pilot demonstrations. This is done to determine the level of treatment and ozone required (e.g. disinfection, biochemical oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), etc.).

Aclarus Ozone Systems Overview

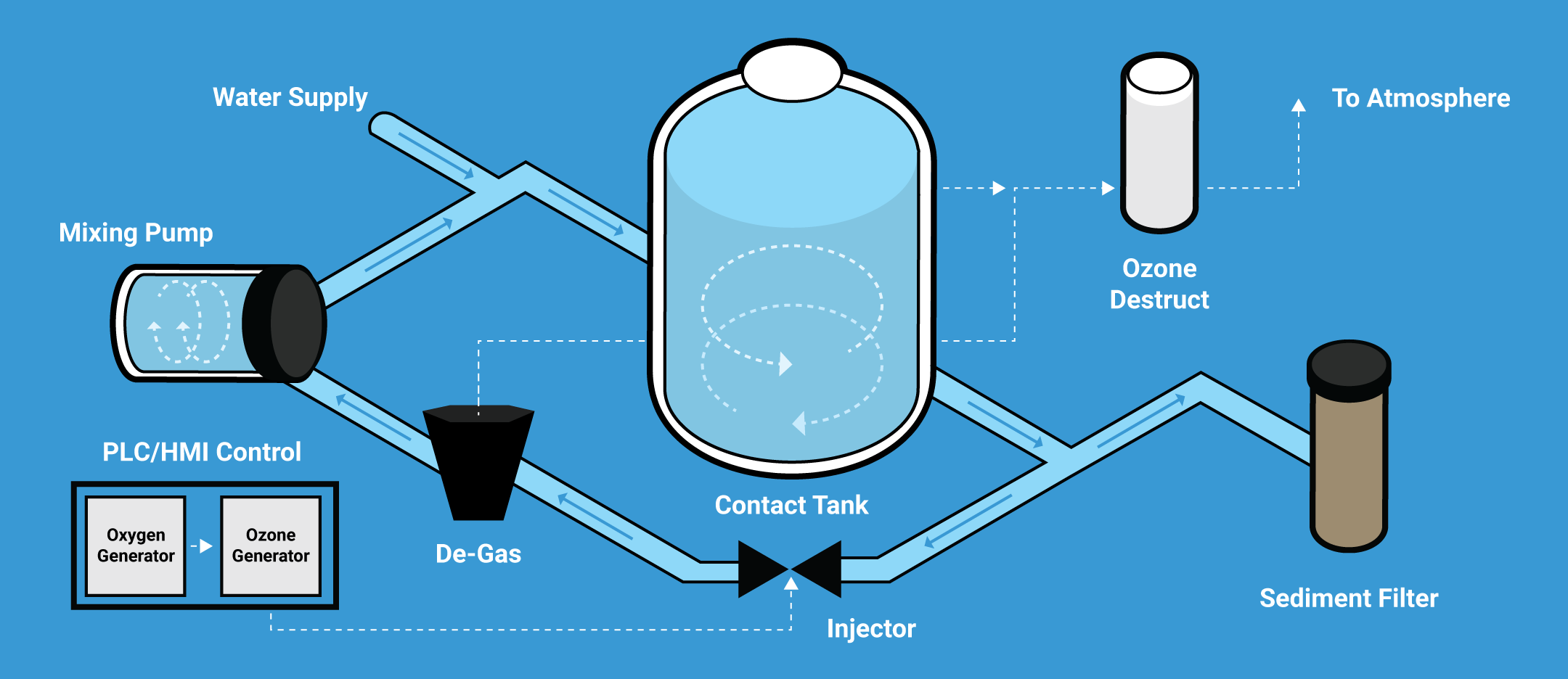

Aclarus systems generate ozone on-site, with an ozone level calibrated for each application and flow rate. The systems are scalable and offer advanced ozone generation, mixing and control systems for reliable and accurate treatment. They can range from simple on/off systems to fully programmable control systems with remote monitoring, alarm integration, ozone dose control and more.’

Aclarus’ advanced saturation systems maximize ozone transfer into water at an average of over 90% compared with traditional transfer rates of approximately 10%. Using inline monitors, the water is measured for automated control to either increase or decrease the ozone level to remain at a setpoint for optimal function.

Aclarus Ozone systems also remove excess ozone from the water and destroy it, limiting potential off-gassing by using integrated air monitors for safe workspaces.

Following ozonation, the water is filtered and then ozone is either removed for incoming use or not removed and sent for use in sanitation. System controls integrate with other control systems and allow for remote monitoring.

Cost Comparison

There is a common perception that ozone is an unaffordable approach to water treatment. In fact, the average operational cost of the Aclarus Ozone System is approximately 5-10 cents per 1,000 litres of treated water, offering the lowest Lifetime Operating Cost (LOC) compared to other technology and a quick Return on Investment.

Aclarus Ozone systems are found in a wide range of applications, including industrial and municipal operations, precisely because they are a cost-effective and reliable treatment. Aclarus advanced and affordable designs have brought ozone to multiple markets that have not previously used ozone.

References

Adams, M. 2016. 2nd Edition. Gold Ore Processing: Project Development and Operations. Elsevier. Oxford, UK.

Carrillo-Pedroza,F.R., F.Nava-Alonso, and A. Uribe-Salas. 2000. Cyanide oxidation by ozone in cyanidation tailings: reaction kinetics. Minerals Engineering 13(5):541-548.

Fu, P., X. Lin, G.Li, Z.Chen, and H.Peng. 2018. Degradation of thiol collectors using ozone at a low dosage: kinetics, mineralization, ozone utilization, and changes of biodegradability and water quality parameters. Minerals 8(11): 477.

Haag W.R., Hoigne J. and H.Bader H. 1984. Improved ammonia oxidation by ozone in the presence of bromide ion. Water Research 18(9):1125-1128.

Jooste, S.H.J. and J. van Leeuwen. 1994. Oxidation of nitrites in mine waters. Ozone: Science and Engineering 16(3):261-271.

Kitis, M., A. Akcil, E. Karakaya, and N.O. Yigit. 2005. Destruction of cyanide by hydrogen peroxide in tailings slurries from low bearing sulphidic gold ores. Minerals Engineering 18 (2005):353–362.

Liu, R., W. Sun, K., Ouyang, L. Zhang, and Y. Hu. 2015. Decomposition of sodium butyl xanthate (SBX) in aqueous solution by means of OCF: ozonator combined with flotator. Minerals Engineering 70 (2015):222-227.

Ma, H.; S.Sun; and M.Xu. 2017. Dephosphorization of flotation wastewater containing organic phosphorus using ozone-coagulation sedimentation method. Chinese Journal of Environmental Engineering 2017:01.

Natarajan, K.W. and I. Iwasaki. 1985. Decomposition of xanthate collectors with ozone in alkaline solutions. Mining, Metallurgy & Exploration 2(1985):241-243.

Nava, F., A.Uribe, and R. Perez, 2003. Use of ozone in treatment of cyanide containing effluents. The European Journal of Mineral Processing and Environmental Protection 3(3):316-323.

Ruffino, B., and M. Zanetti. 2019. Orthophosphate vs. bicarbonate used as a buffering substance for optimizing the bromide-enhanced ozonation process for ammonia nitrogen removal. Science of the Total Environment 692(2019):1191-1200.

Yan, P., G. Chen, M. Ye, S.Sun, H.Ma, and W. Lin. 2016. Oxidation of potassium n-butyl xanthate with ozone: products and pathways. Journal of Cleaner Production 139 (2016): 287-294.

Yang, M., Uesugi, K. and H. Myoga. 1999. Ammonia removal in bubble column by ozonation in the presence of bromide. Water Research 33(8):1911-1917.

Yang, M., Uesugi, K. and H. Myoga. 2000. Study on By-Products of Ozonation during Ammonia Removal under the Existence of Bromide: Factors Affecting Formation and Removal of the ByProducts. Ozone: Science and Engineering 22(3):23-29.

Do you have an ozone related question?

Read past responses or submit your question for Adam Doran Aclarus Co-Founder!