Greenhouses and Hydroponics

Ozone is a sustainable and environmentally safe treatment for water that is chemical-free, energy-efficient and cost-effective.

For the hydroponics sector, Aclarus Ozone provides water treatment solutions for the following operational challenges:

Incoming Water and Processing

Wastewater and Re-Use

Clean-In-Place (CIP) Sanitation

Stored Water and Shock Cleaning

Ozone Advantages for Greenhouse and Hydroponics

Ozone is increasingly used in the greenhouse and hydroponics sector because it has numerous advantages over traditional disinfection methods. Supplementing or replacing an existing system with an ozone system has the potential to boost a company’s advantage over its competitors.

Ozone has the following advantages:

✓ Classified as Organic - No Harmful Residual Left in the Water

✓ Compliant with the Canadian Food Inspection Agency (CFIA) and the US Food and Drug Administration (FDA) for Food and Surface Sanitization

✓ Neutralizes Unhealthy Metals in the Water, Like Iron, Sulphur and Manganese

✓ Removes any Colour, Taste or Smell

✓ Removes Contaminants Such as Pesticides, Organic Matter, Various Microbes, Pharmaceuticals and Micro-Plastics

✓ Disinfects and Sanitizes Equipment and Surfaces Quickly, Without Chemicals

✓ Produced Onsite and On Demand, Removing the Need to Purchase, Store and Physically Handle Chemicals.

MIREPOIX FARM - CASE STUDY

Timothy Noxon, Owner of Mirepoix Farm found immediate benefits for his greenhouse operation after installing his Aclarus Ozone system.

”The seedlings are more robust, resulting in better quality crops and increased yields given we now have more growing cycles throughout the year.”

Aclarus Water Treatment Solutions

Incoming Water Processing

Incoming water treatment can be an important step for assured quality, especially for well or surface-water sources. It is safe for roots and plants and adds oxygen to the water.

Ozone is classified as organic and can be used “on demand” to produce premium quality water that is fully disinfected and is rich in oxygen, which optimizes plant growth without phytotoxicity. Ozone can treat and filter with ozone removed or in some facilities a residual amount can be left in the water to protect against bacteria, biofilm and other contaminants.

In fact, studies show that ozone can control a number of common pathogens with little potential for phytotoxic effects at lower levels. (Zheng et al., 2007).

Ohashi-Kaneko et al. (2009) investigated the effect of using a nutrient solution mixed with ozonated water at a concentration of 1.5 mg L-1 (ppm) on hydroponically grown tomatoes.

Their study tested the phytotoxicity of the residual ozone and determined no detrimental effects to the plant growth or the water quality while noting increased dissolved oxygen levels during the first 30 minutes after application to the roots.

A similar study done by Graham et al. (2011) was conducted in which cucumber and tomato plants grown in rockwool were subjected to single high doses of ozone (0-20 mg L-1 O3) and then repeated low doses (0-6 mg L-1 O3) to assess the phytotoxicity on the plant growth. The results showed that there was no negative effect on the shoot dry weight or leaf area.

Ozone is compliant with Health Canada, the CFIA and the US FDA for both food and surface sanitization when applied correctly. Aclarus Ozone offers NSF-61 compliant systems for assured food grade quality.

Clean-In-Place (CIP) Sanitation

Ozone is gentler than many common chemicals currently used for sanitation when using a properly designed system. Aqueous ozone can be safely used for cleaning surfaces – such as equipment, walls, floors and tables – reducing costs for soap, acid and cleaners. Ozone is made on-site instantly and for CIP the ozone dose is set to meet government regulations either manually or with in-line monitoring.

Surfaces are cleaned using industry standard practices and ozone is applied as a final rinse to sanitize the surface, destroying bacteria, viruses, fungi, and spores. Only cold water is required, and no subsequent rinse is needed, as ozone leaves no residue. This saves water and power costs.

Replacing or supplementing chemicals with ozone for CIP, is more efficient and effective and also improves wastewater quality. Chemical residuals can have negative impacts on wastewater which can lead to regulatory overage charges and impacts with septic systems; ozone improves wastewater quality and then breaks back to oxygen and water.

Ozone tests at a fruit and vegetable pilot plant at California Polytechnic State University showed ozone’s ability in reducing microbiological loading with a 2.0 ppm level that was sprayed on the surfaces to be sanitized. No other cleaning was used to ensure all reductions in bacteria were attributed to the aqueous ozone.

Fujiwara at al. (2011) found that intensive spraying of plants of ozonated water at levels as high as 8.0 ppm of ozone for airborne disease control does not cause any visible injury to the fruit-vegetable seedlings.

Aclarus Ozone Systems Overview

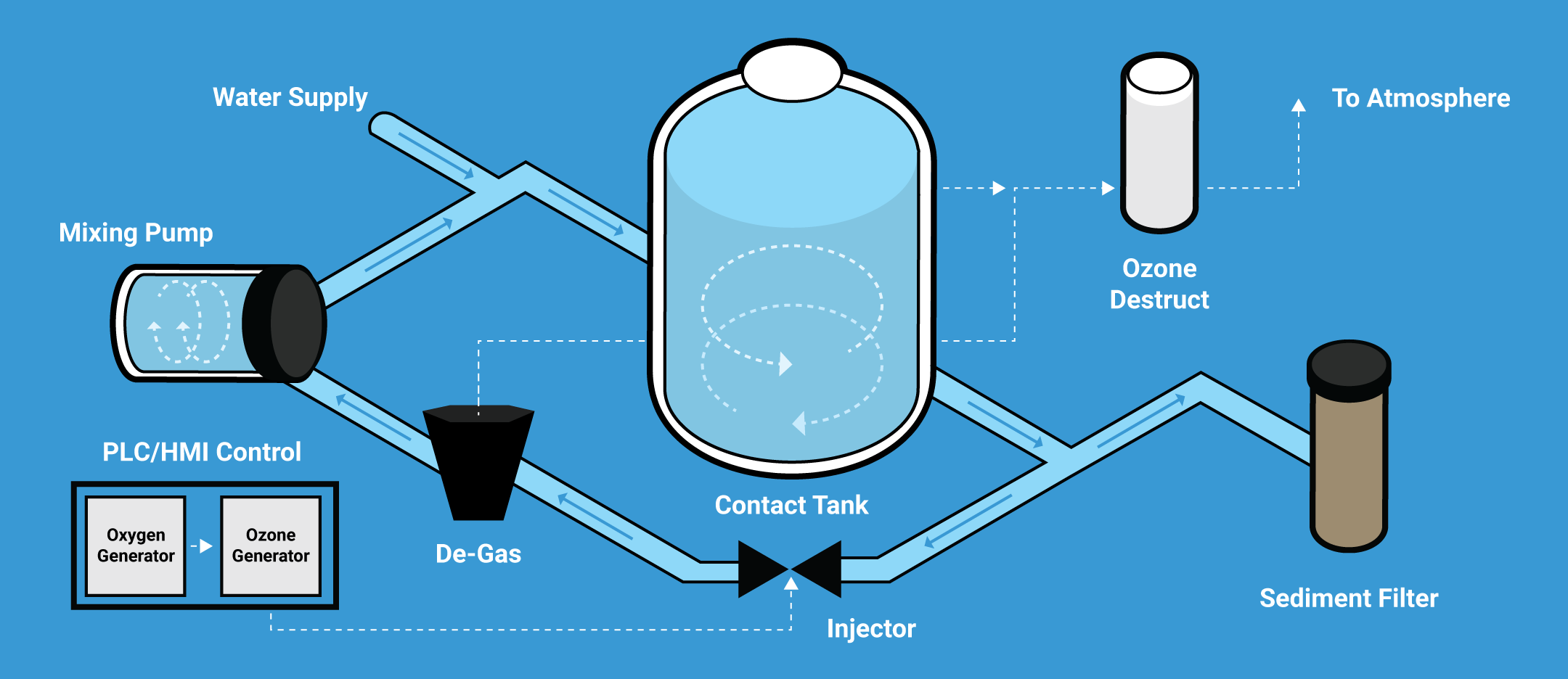

Aclarus Ozone systems generate ozone on-site, with an ozone level calibrated for each application and flow rate. The systems are scalable to accommodate microbreweries to large-scale operations and they offer advanced ozone generation, mixing and control systems for reliable and accurate treatment.

Aclarus systems are easily retrofitted into existing facilities and are modular, to allow expansion when required. They can range from simple on/off systems to fully programmable control systems with remote monitoring, alarm integration, ozone dose control and more.

Aclarus’ advanced saturation systems maximize ozone transfer into water at an average of over 90% compared with traditional transfer rates of approximately 10%. Using inline monitors, the water is measured for automated control to either increase or decrease the ozone level to remain at a setpoint for optimal function.

Following ozonation, the water is filtered and then ozone is either removed for incoming use or remains in the water for use in sanitation. In many cases ozone can work in a closed loop CIP to greatly lessen water use and waste.

Aclarus Ozone systems also remove excess ozone from the water and destroy it, limiting potential off-gassing by using integrated air monitors for safe workspaces.

Cost Comparison

There is a common perception that ozone is an unaffordable approach to water treatment. In fact, the average operational cost of the Aclarus Ozone System is approximately 5-10 cents per 1,000 litres of treated water, offering the lowest Lifetime Operating Cost (LOC) compared to other technology and a quick Return on Investment.

Aclarus Ozone systems are found in a wide range of applications, including industrial and municipal operations, precisely because they are a cost-effective and reliable treatment. Aclarus advanced and affordable designs have brought ozone to multiple markets that have not previously used ozone.

References

Rosenblum, J., C. Ge, Z. Bohrerova, A. Yousef and J. Lee. 2012. Ozonation as a clean technology for fresh produce industry and environment: sanitizer efficiency and wastewater quality. Journal of Applied Microbiology 113:837-845.

Do you have an ozone related question?

Read past responses or submit your question for Adam Doran Aclarus Co-Founder!