Breweries

Ozone is a sustainable and environmentally safe treatment for water that is chemical-free, energy-efficient and cost-effective.

For the brewery industry, Aclarus Ozone provides water treatment solutions for the following operational challenges:

Incoming water for use in the brewing process

Clean In Place (CIP) Sanitation

Wastewater and Re-Use

Ozone Advantages for Breweries

Ozone is used in brewery operations because it has numerous advantages over traditional (chemical) disinfection methods.

Supplementing or replacing an existing system with an ozone system has the potential to reduce costs and time. In fact, ozone is now the disinfection treatment of choice for a variety of food sectors – including beer/wine, aquaculture, hydroponic and others – due to its multi-treatment ability and assured treatment.

Ozone has the following advantages for brewery operations:

✓ Classified as Organic - No Harmful Residual Left in the Water

✓ Compliant with the Canadian Food Inspection Agency (CFIA) and the US Food and Drug Administration (FDA) for Food and Surface Sanitization

✓ Neutralizes Unhealthy Metals in the Water, Like Iron, Sulphur and Manganese

✓ Removes any Colour, Taste or Smell

✓ Removes Contaminants Such as Pesticides, Organic Matter, Various Microbes, Pharmaceuticals and Micro-Plastics

✓ Disinfects and Sanitizes Equipment and Surfaces Quickly, Without Chemicals

✓ Produced Onsite and On Demand, Removing the Need to Purchase, Store and Physically Handle Chemicals.

The George Brewery - Case Study

The George Brewery strives for the best quality beer with the least environmental impacts and Aclarus Ozone provided their water treatment and sanitation solution.

“It doesn’t make sense to use anything other than ozone for so many reasons...the quick ROI and cost savings, the environmental benefits, not to mention premium quality beer.”

-Head Brewer Steven Herald

Aclarus Water Treatment Solutions

Incoming Water

Incoming water treatment can be an important step for assured quality, especially for well or surface water sources. Ozone works on demand to disinfect and treat water without salt or chemicals. The treated water is of premium quality, with no chemical residual.

From wells or municipal water, ozone will remove chlorine, metals and even many micro-pollutants such as hormones and by-products. Importantly, ozone removes colour, taste and smell from the water, which is why it is the standard in bottled water treatment.

Ozone has no impact on pH levels in the water and has no residual as it breaks down to oxygen before use.

This water is also suitable for other uses in the facility to reduce costs for soap, acid and cleaners.

Clean In Place (CIP) Sanitation

Aqueous ozone is pre-approved by Health Canada for cleaning and can be used for multiple purposes in breweries. It is commonly used for surfaces (equipment, walls, floors, tables) as well as kegs, bottles, fermentation tanks and more.

Following industry standard practices, ozone is applied as a final rinse sanitation to treat bacteria, viruses, fungi, and more. Only cold water is required, and no final rinse needed, as ozone leaves no residual. This saves time, water and energy costs.

Ozone CIP also benefits run-off water from the cleaning process because any residual ozone can reduce contaminants in the run-off water, helping to keep drain lines clear. Since only oxygenated water is produced, the run-off is safe for discharge without concerns for septic or municipal systems.

Ozone offers an ideal re-use option for final rinse in a closed loop, reducing the amount of water used and wasted. Ozone is also a more effective pre-rinse and can be used from fresh water or re-used water.

Wastewater and Re-Use

Wastewater from breweries presents both cost and regulatory challenges.

Ozone safely treats wastewater, helping to keep drain lines clear and only producing oxygenated water that is safe to discharge without concerns for septic systems or municipal systems. It is a cost-effective way to help brewers achieve regulatory compliance and reduce fees and fines.

Ozone Aclarus designers quickly assess the wastewater needs for each brewery and design a solution to fit the need through testing and/or pilot demonstrations. This is done to determine the level of treatment and ozone required (e.g. disinfection, BOD, COD, TSS, etc).

By using ozone in the CIP process, the run-off water requirements are lessened, “reducing at least by 50% the organic load in the cleaning waste waters produced” (Canut et al2013). This is due to ozone not contributing to COD and its ability to treat many contaminants prior to discharge.

Ozone is also an effective treatment for water that is re-used for non-potable purposes – an obvious environmental benefit that also results in cost savings.

Aclarus Ozone Systems Overview

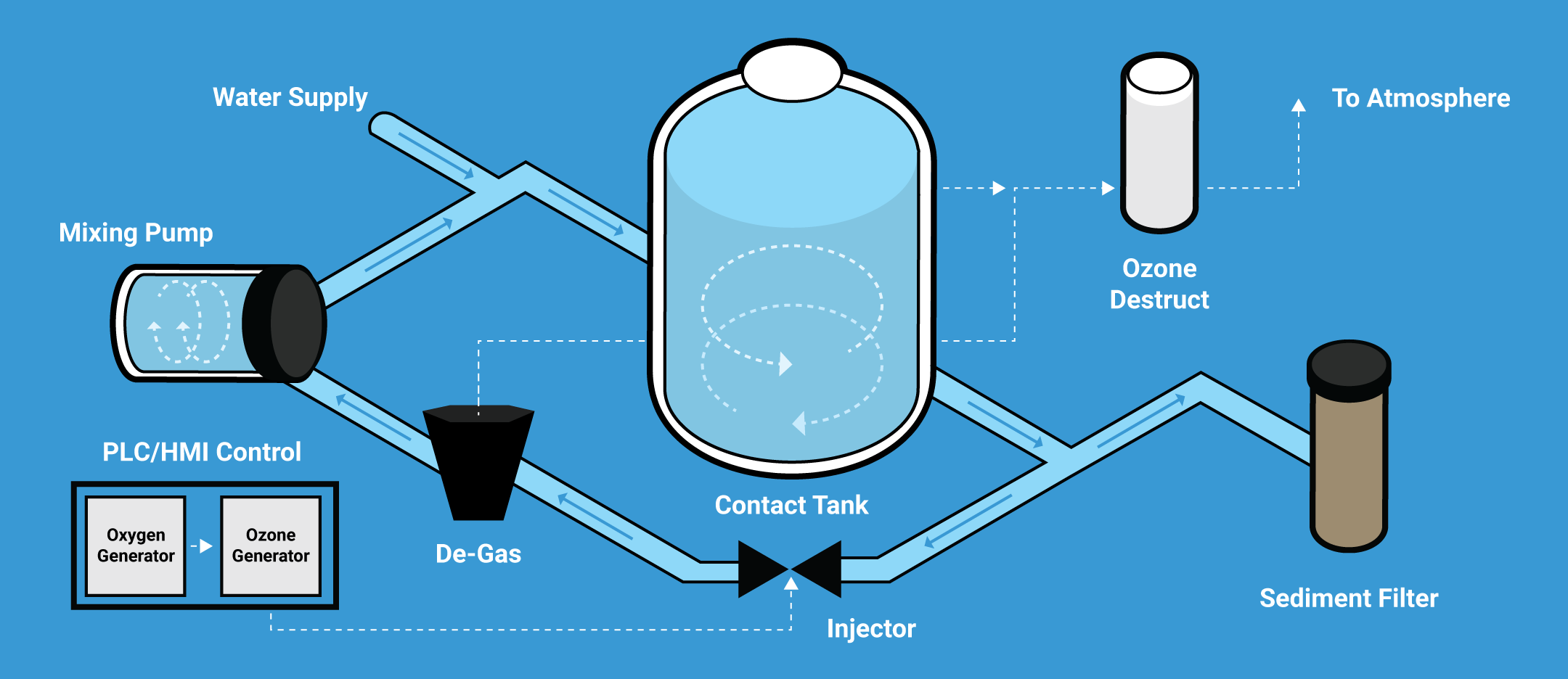

Aclarus Ozone systems generate ozone on-site, with an ozone level calibrated for each application and flow rate. The systems are scalable to accommodate microbreweries to large-scale operations and they offer advanced ozone generation, mixing and control systems for reliable and accurate treatment.

Aclarus systems are easily retrofitted into existing facilities and are modular, to allow expansion when required. They can range from simple on/off systems to fully programmable control systems with remote monitoring, alarm integration, ozone dose control and more.

Aclarus’ advanced saturation systems maximize ozone transfer into water at an average of over 90% compared with traditional transfer rates of approximately 10%. Using inline monitors, the water is measured for automated control to either increase or decrease the ozone level to remain at a setpoint for optimal function.

Following ozonation, the water is filtered and then ozone is either removed for incoming use or remains in the water for use in sanitation. In many cases ozone can work in a closed loop CIP to greatly lessen water use and waste.

Aclarus Ozone systems also remove excess ozone from the water and destroy it, limiting potential off-gassing by using integrated air monitors for safe workspaces.

Cost Comparison

There is a common perception that ozone is an unaffordable approach to water treatment. In fact, the average operational cost of the Aclarus Ozone System is approximately 5-10 cents per 1,000 litres of treated water, offering the lowest Lifetime Operating Cost (LOC) compared to other technology and a quick Return on Investment.

Aclarus Ozone systems are found in a wide range of applications – including municipal operations – precisely because they are a cost-effective and reliable treatment. There is significant independent research demonstrating the savings for municipalities when switching to ozone.

There is significant independent research demonstrating the savings for breweries when switching to ozone. For breweries of all sizes, the savings quickly convert into increased profits. The savings are found in three categories: less water used; no chemicals to be purchased or stored; and, lower energy costs. Research articles noted ozone’s ability in “…reducing the amount of water used/discharged (50%)” (Canut et al.).

For those dealing with regulatory overage fees, the savings is even more impactful.

References

Arranz, Miguel Ángel Prieto, Dr. G. Schories 2007. The use of aqueous ozone for cleaning operations in breweries. IOA Conference and Exhibition Valencia, Spain - October 29 – 31, 2007.

Canut, A., Llorca, I., Soro, R, Pascual, A 2013. Reducing costs by integrating ozonated water in the CIP systems Research Association for Food Industry (ainia). Quality, food safety and environment department Valencia.

Terry, Patricia A 2010. Application of Ozone and Oxygen to Reduce Chemical Oxygen Demand and Hydrogen Sulfide from a Recovered Paper Processing Plant. Department of Natural and Applied Sciences, University of Wisconsin-Green Bay, 2420 Nicolet Drive, ES317, Green Bay,WI 54311, USA.

Hanley-Onken, Erika 2013. Ozone: A New Water Management Paradigm. Pharmaceutical Manufacturing Magazine.

Do you have an ozone related question?

Read past responses or submit your question for Adam Doran Aclarus Co-Founder!